NCSIMUL 4CAM

Streamlined, bi-directional & seamless End-to-End machining process

NCSIMUL 4CAM is enriching the existing CAM process to simplify CNC programming. It provides unparalleled flexibility on the shopfloor. It allows to change, in one click, the target machine, without any CAM reprogramming.

From the main CAM (e.g., CAM solutions from Hexagon such as ESPRIT TNG, EDGECAM, SURFCAM, VISI Machining and ALPHACAM or other CAM solutions such as CATIA CAM, NX CAM, Creo CAM, Mastercam, hyperMILL, POWERMILL, TOPSOLID CAM etc.) or existing CNC programs (G-code format), NCSIMUL 4CAM generates directly (without external post-processor), CNC native programs, verified and optimized taking into account the physical means of the workshop (tools, cutting conditions, kinematics, machine controllers …)

CHALLENGES

|

BENEFITS

|

Features at a glance :

- « Hybrid » programming, for a seamless legacy program recovery

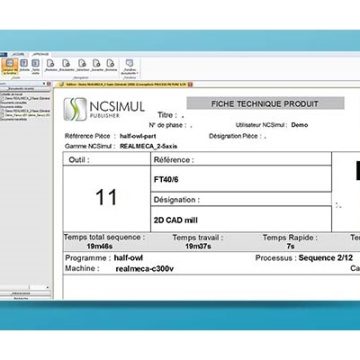

- Error-free native CNC code programming, as an all-in-one solution

- No more external postprocessor, streamlining the CNC process

- One-click re-programming, for complete flexibility

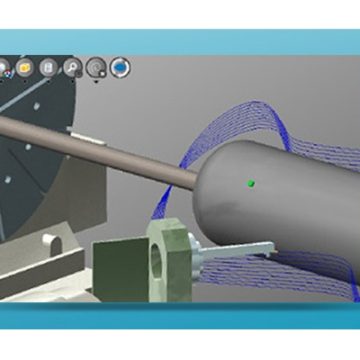

- Dynamic rest material management, for a peerless programming comfort

Reviews

There are no reviews yet.