VISI is acknowledged as one of the world’s leading PC based CAD CAM software solutions for the Mould & Die industries.

It offers a unique combination of applications, fully integrated wireframe, surface and solid modelling, comprehensive 2D, 3D and 5 axis machining strategies with dedicated high speed routines. Industry specific applications for plastic injection tool design including material flow analysis and progressive die design with step-by-step unfolding provide the toolmaker with unsurpassed levels of productivity.

Hexagon offers dedicated solutions that eliminate the links between varying software suppliers and the solid-to-surface or CAD CAM geometry conversions required by traditional systems.

VISI offers the following applications:

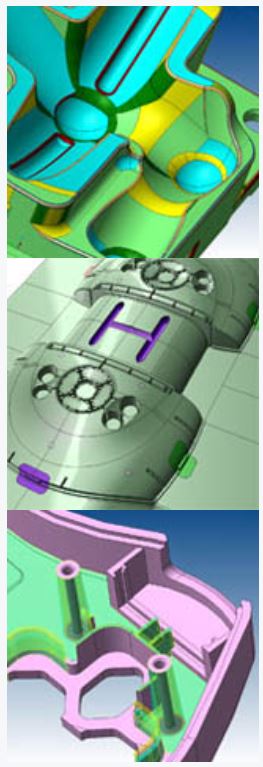

VISI ModellingVISI Modelling – Powerful Surface Modelling & Solid Modelling SoftwareVISI Modelling is the foundation of all VISI products and provides a robust and powerful solid and surface modelling system based around the industry standard Parasolid® kernel. Combined with Hexagon’s surface technology, model analysis and 2D design, VISI Modelling offers complete flexibility to construct, edit or repair the most complex 3D data. Features at a glance:

|

|

VISI AnalysisVISI Analysis – Solutions for the validation & preparation of model geometryWhen working with imported data, the quality of the model is an important consideration. Finding potential problems at an early stage within the project will greatly simplify the task of the designer and generate huge time savings further along the design process. Features at a glance:

|

|

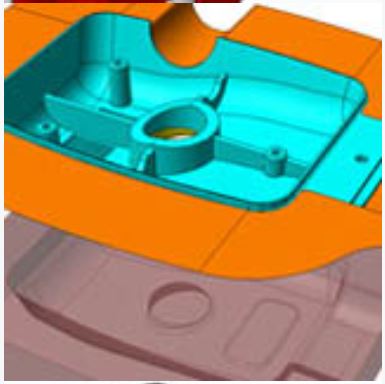

VISI MouldVISI Mould – Mould Tool Design solutions for Mould DevelopmentVISI Mould provides the complete mould tool design solution based on industry specific automation that guides the user through the mould development process. Dynamic operation previews provide the designer with a ‘real time’ view of how component changes will affect the tool design. Features at a glance:

|

|

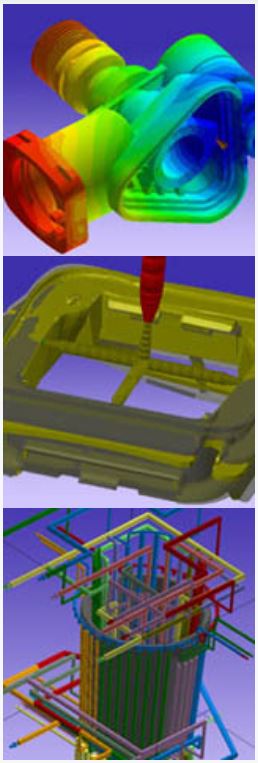

VISI FlowVISI Flow – Injection Simulation Software for the Mould Making ProcessAll areas of moulded component creation can benefit from the optimisation of mould tool design and moulding process parameters. Part designers, mould makers and moulders will all benefit from using Hexagon’s innovative technology for injection simulation to achieve cost effective and reliable mould designs and the optimum moulding conditions. VISI Flow is a unique prediction tool, ideal for pre and post production analysis and concurrent engineering of injection moulded plastic components. Features at a glance:

|

|

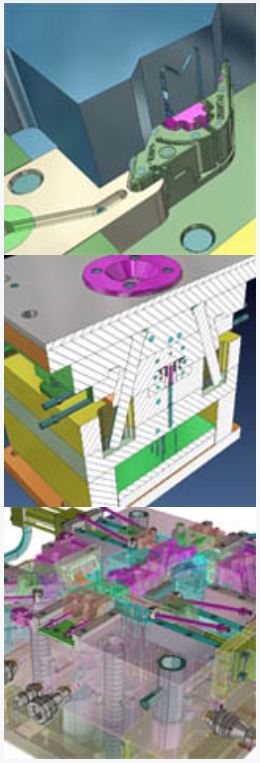

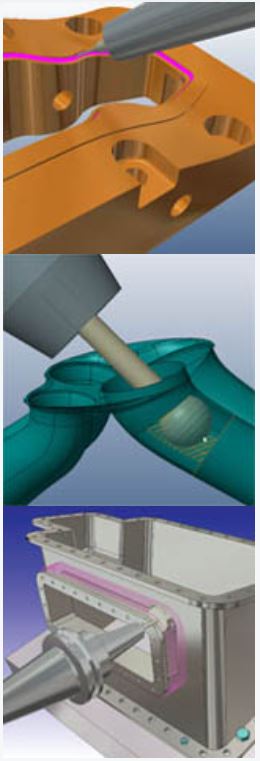

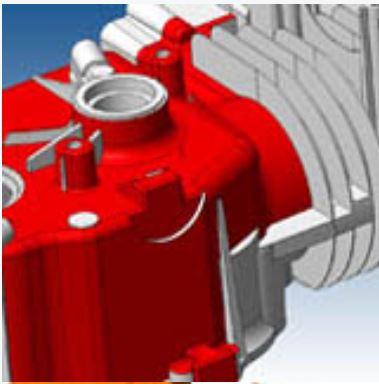

VISI ElectrodeVISI Electrode – EDM Electrode Creation & Electrode Manufacturing SolutionsVISI Electrode is an automated module for the creation and management of electrodes and their holders for the manufacture of detailed and hard to machine features on mould and press tools. Comprehensive holder design, simulation and collision checking ensures that the electrode will operate right first time. EDM electrode creation can be one of the most complex and time consuming projects for any mould or die maker. The VISI suite of products offer a solution at every point of the manufacturing process from design to manufacture. Even the most experienced electrode designer will benefit from the knowledge based automation provided by VISI Electrode. Features at a glance:

|

|

VISI ProgressVISI Progress – Dedicated solutions for Progressive Die Design and Press ToolsIndustry specific functionality provides a more productive and efficient design experience. Helping the designer with intelligent decisions will reduce the potential for error and greatly improve manufacturing productivity. Features at a glance:

|

|

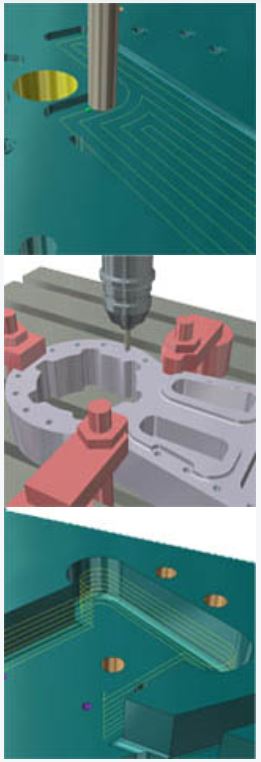

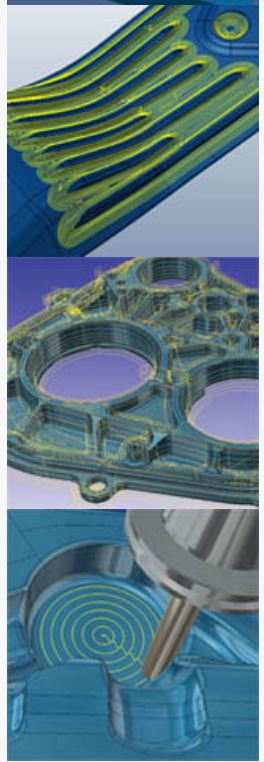

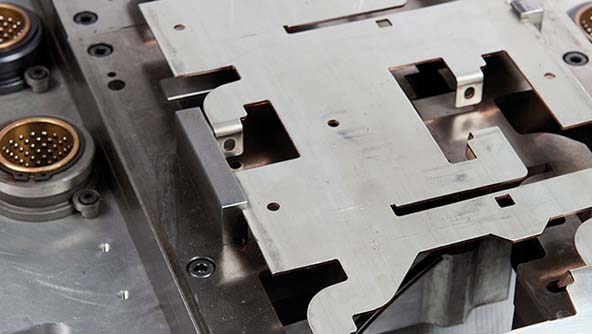

VISI Machining 2DVISI Machining 2D – 2D machining toolpaths from wireframe & solid geometryVISI Machining 2D provides a practical, intuitive and simple solution for CNC programming including 4 and 5 axis indexing. Knowledge based feature recognition will automatically select features directly on the solid geometry and create reliable milling and drill cycle toolpaths. Features at a glance:

|

|

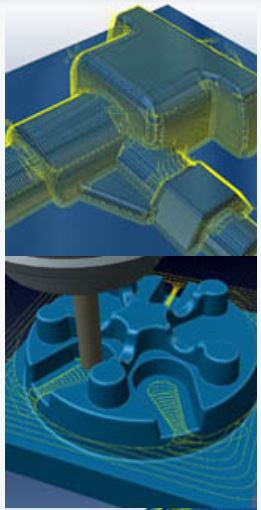

VISI Machining 3DVISI Machining 3D – Intelligent 3D Toolpaths with High Speed Milling routinesVISI Machining 3D creates intelligent toolpaths on the most complex 3D parts. Dedicated high speed milling techniques and built in smoothing algorithms create highly efficient NC code. Intelligent toolpaths will reduce cycle times on your machine, improve productivity and continuously produce high quality components. Features at a glance:

|

|

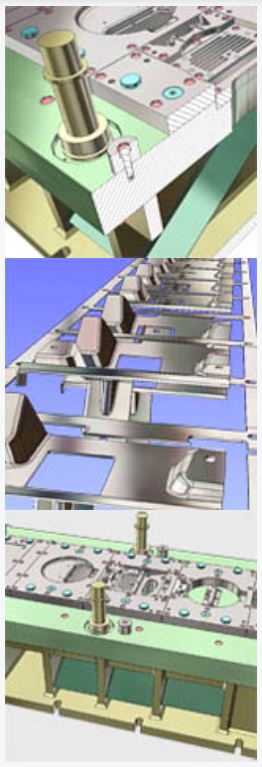

VISI Machining 5 AxisVISI Machining 5 Axis – Efficient Multi-Axis toolpaths with collision detection5 Axis Machining has traditionally been regarded as advanced technology best suited to the aerospace and automotive industry. 5 axis machining offers many advantages, all of which are now being applied to the mould and die sector. VISI Machining provides the operator with a productive solution for creating highly efficient toolpaths with advanced collision control for the most complex 3D data. Features at a glance:

|

|

VISI PEPS WireVISI PEPS Wire – Reliable Wire EDM toolpaths and proven CNC CodeVISI PEPS-Wire incorporates the industry leading PEPS Wire EDM CAM system, developed specifically for the precision engineering, tool-making, mould & die, press and extrusion tool industries, within the VISI design environment. Fully feature based, VISI PEPS-Wire provides automatic feature recognition of wire features including tapered, variable taper and 4 axis directly from solid geometry. Features are easily machined creating reliable Wire EDM toolpaths and proven CNC code for all Wire EDM machine tools. Features at a glance:

|

|

VISI BlankVISI Blank – Automated 2D blank development from complex 3D modelsVISI Blank is an integrated solution for the development of 2D blank shapes from complex 3D models. It is particularly useful in the generation of blank forms for the sheet metal, progressive die, press tooling and crash tooling industries. VISI Blank benefits from seamless integration with the acclaimed VISI Modelling software, using the industry standard Parasolid kernel combined with Hexagon’s proprietary surface modeling and 2D design technology. VISI Blank is designed for estimators, engineers, sheet metal product designers and tool and die makers to optimise the development of sheet metal components and provide valuable analysis of material behaviour during the forming process. For the estimator a quick blank representation can be achieved in minutes to highlight potential manufacturing problems, determine material costs and to streamline the production process. The designer can benefit from the quick analysis provided by VISI Blank to determine areas of a component design which may need to be modified to provide lower manufacturing costs. For the toolmaker, the application is invaluable for identifying areas of a component that will require to be drawn as opposed to multiple forming operations. Features at a glance:

|

|

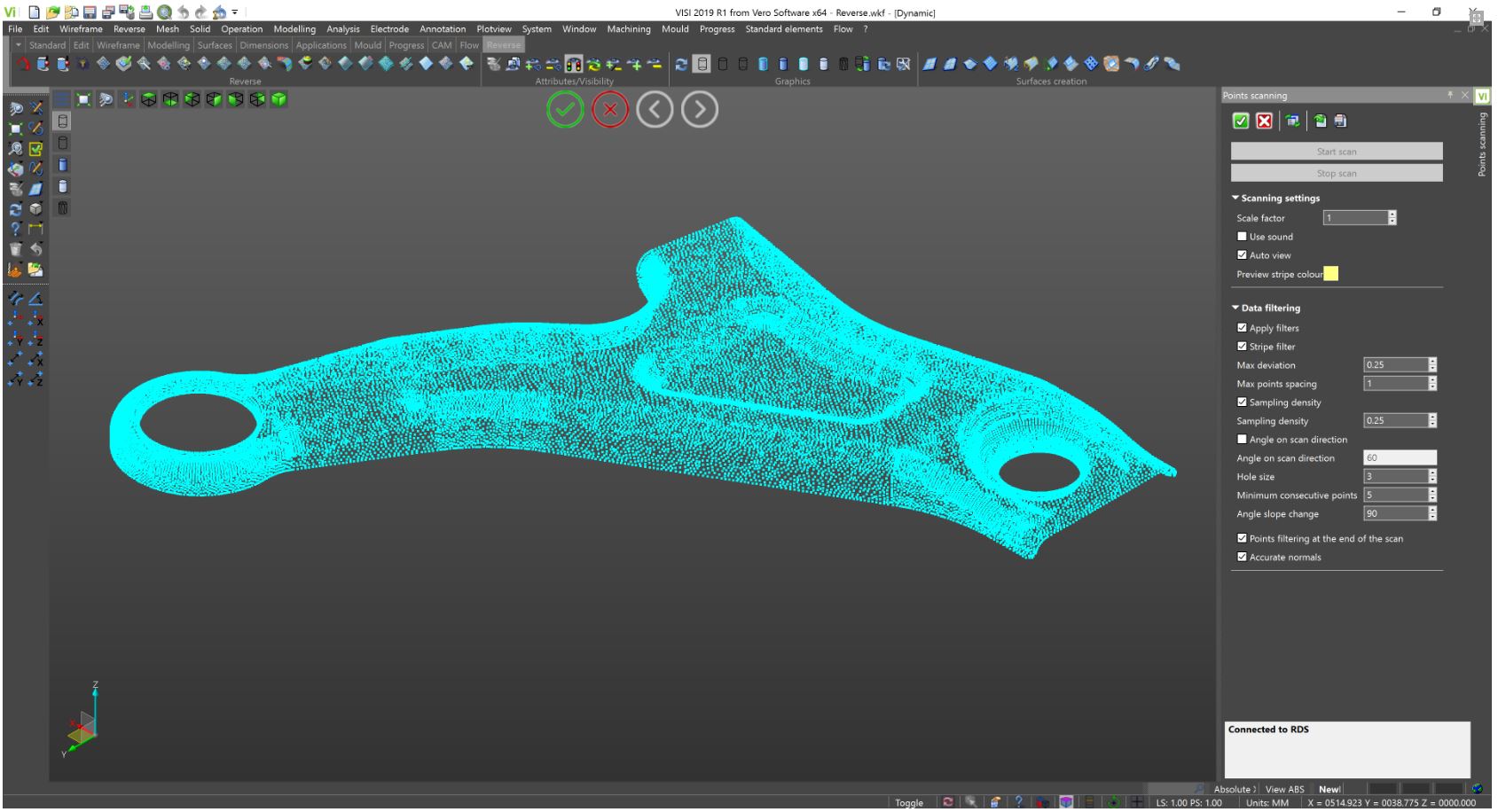

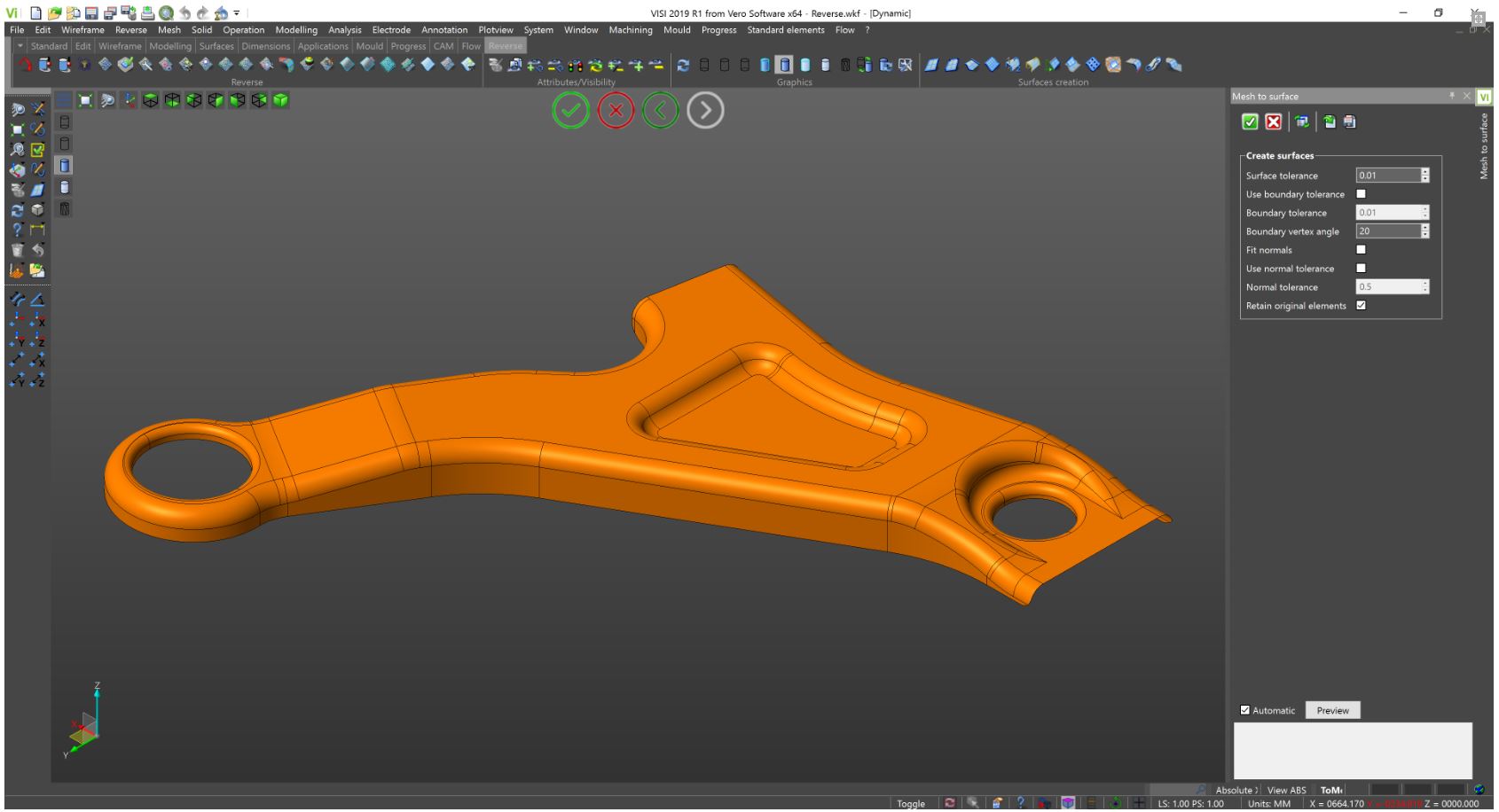

VISI ReverseThe shortcut from 3D scan to manufacturingVISI Reverse, an intuitive module that can be added to the mould and stamping industry leader VISI application from Hexagon Manufacturing Intelligence, combines hybrid modelling CAD functionality with 3D scan data processing abilities so that easily customers can create fully compatible editable solid models starting from digitized/scanned data. Features at a glance:

|

|

Reviews

There are no reviews yet.